Monocrystalline Vs Polycrystalline Modules: Differences & Factors

Solar modules are made up of cells and these cells have a physical make-up that determines how they respond to sunlight and in turn how they generate power.

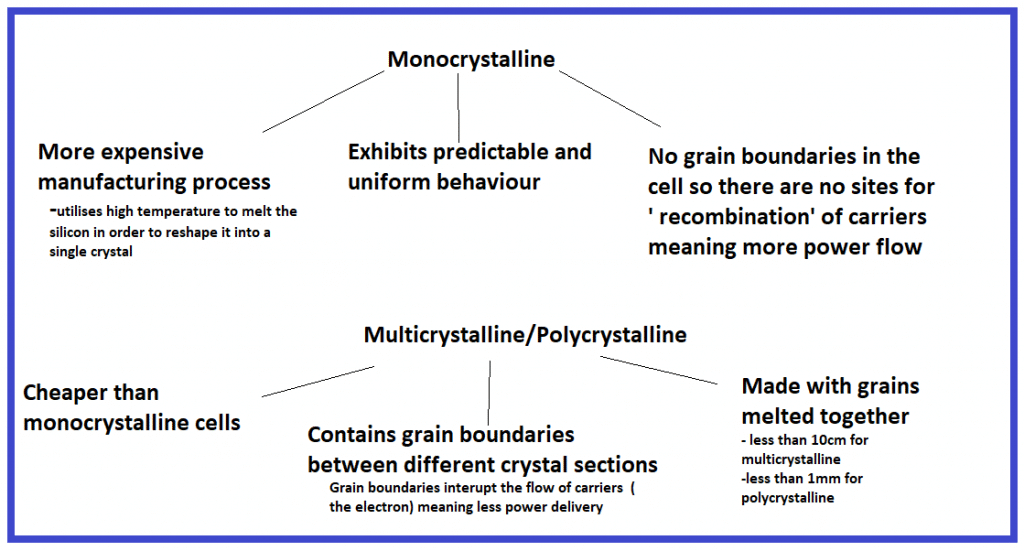

Basically because of the manufacturing method monocrystalline has a higher cost than polycrystalline modules however it also has less electrical losses associated with its operation so monocrystalline modules deliver higher power.

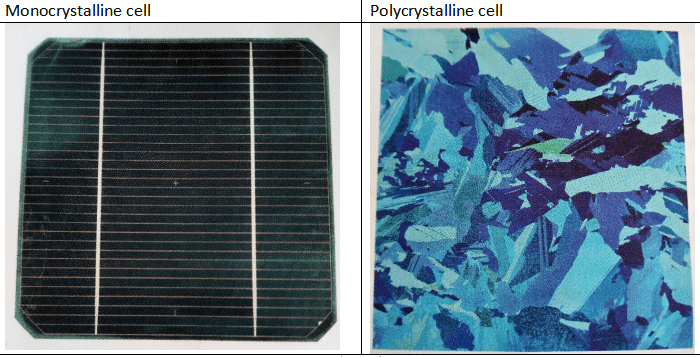

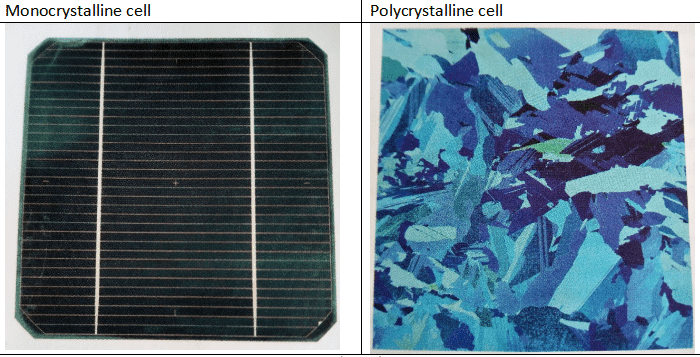

Monocrystalline modules can be spotted via the cells with their dark surface under light and their uniform surface however the polycrystalline modules are made up of cells that contain multiple grains and so reflect light via different colours of blue.

What is the difference between Monocrystalline modules and Polycrystalline modules?

The image above is from Planning and Installing Photovoltaic Systems, German Solar Energy Society

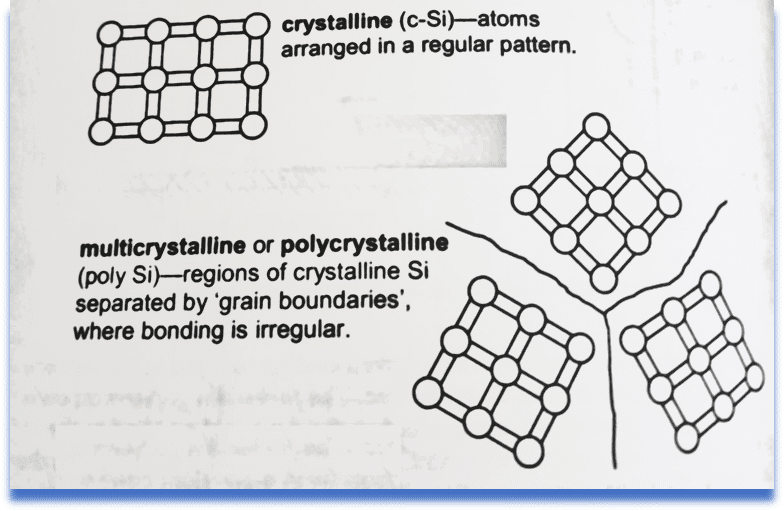

From the image below we can see the makeup of crystalline, or monocrystalline, and multi or polycrystalline cells.

The arrangement of the atoms in a monocrystalline cell is more ordered in its crystal structure with each atom lying in a specific position to build up a crystal-like structure which is the same throughout, meaning that if you took a microscope to the cell, the structure would be the same in any position.

This enables the material to act in a way such that each part of the cell produces power in the same way and this can be predicted by how the cell was made.

The production of this monocrystalline involves very high temperatures in the melting of the polycrystalline start material at temperatures around 1420 degrees celsius so the manufacturing expense is higher for monocrystalline as opposed to multi/polycrystalline which only needs to be heated in such a way to fuse together the separate silicon grains.

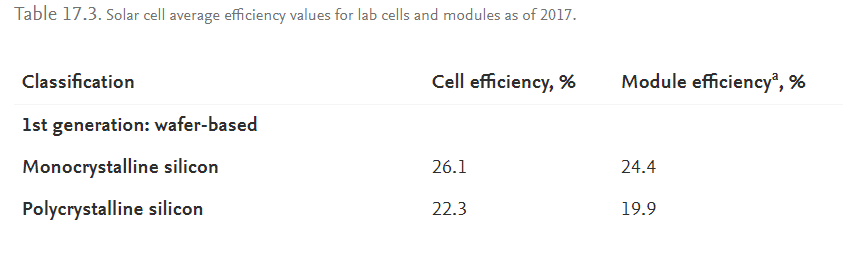

As of 2019 the laboratory cell and module efficiencies of mono and polycrystalline are shown below:

The image above from Nikolay Belyakov, in Sustainable Power Generation, 2019

It can be seen in laboratory conditions that the module efficiencies of monocrystalline modules are significantly higher than the module efficiency of polycrystalline modules.

This translates into a greater performance and conversion of solar energy into usable electrical energy and thus we see why, although costlier, the monocrystalline modules generate more power than their polycrystalline counterparts.

The laboratory conditions are quite enhanced compared to the real world performance due to:

- Commercially available modules being a cheaper replica of laboratory testing performance modules

- Less than ideal light conditions

- Module degradation over time

- Operating temperatures higher than test condition temperatures of 25 degrees

So in reality on your rooftop, the performance of the modules will be less than what is stated above, with commercially available monocrystalline modules having efficiencies of around 20-22%, such as the Sunpower SPR-MAX3-400 which has a rated efficiency of 22.6%.

However, the corresponding efficiency for 400W polycrystalline modules such as the Top Sun TS-M400 is around 15-17% meaning you need a larger sized module to get the same sized output when it comes to comparing polycrystalline with monocrystalline modules.

What this means is that installing with monocrystalline allows you to maximise your power production on a roof where space is limited.

Written by Anders Jensen

1300-713-998

1300-713-998